Design

First of all, a cutting-edge technical department capable of assessing customer requests and translating them into technical projects and moulds suitable for the next process. Specialised staff ready to understand and optimise needs, draw up specifications and industrialise the production process.

Prototypes

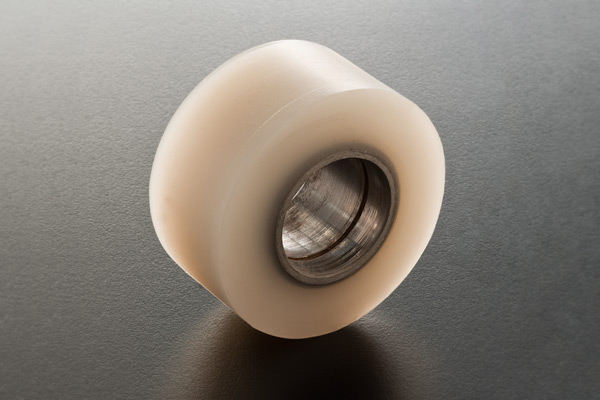

This is the phase in which the basic polymer and the appropriate mixture are chosen, the moulding methods are identified and samples of various items are made to gauge equipment, define the production standard and assess the effectiveness and suitability of the prototype, together with the customer, which will then go into mass production.

Production

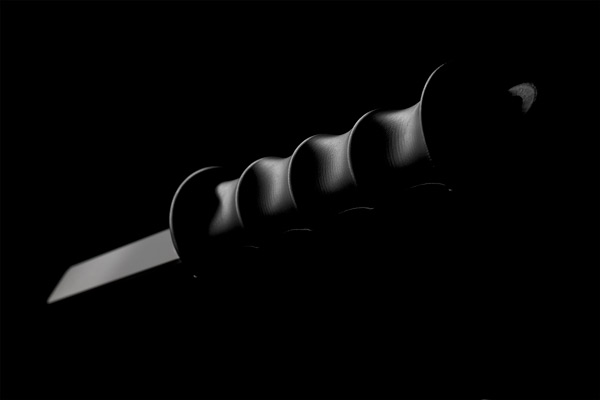

The prototype system includes the use of steel moulds and heated platen presses (200 °C) to vulcanize rubber. Final mass production follows, including injection or compression moulding by means of hydraulic presses.

Finishes

Personnel specialised in finishing, manually completes the items produced, removing imperfections and checking each item one-by-one for correct manufacture and seal.

Sale

As well as producing to specific customer drawings, moulds or requests, we are also able to make and sell our own standard products for use in the main sectors we deal with.